Lubricating Solutions for Pumps, Compressors, and Vacuums

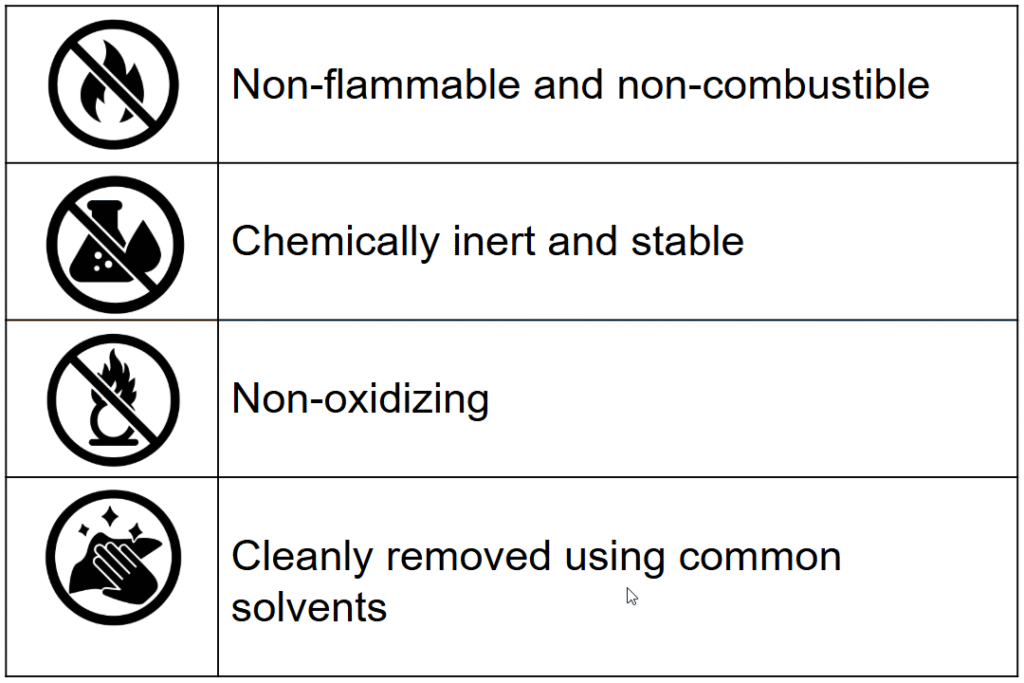

Halocarbon lubricants are nonflammable, oxygen-compatible, and chemically inert oils and greases engineered for pumps, compressors, and vacuum systems. By forming a stable lubricating film across shafts, bearings, seals, rotors, and vanes, they reduce wear, extend equipment life, and keep processes running reliably.

Unlike conventional hydrocarbon pump oils, Halocarbon engineered lubricants deliver unmatched safety and reliability in demanding industrial, chemical processing, and cryogenic environments.

More Than a Lubricant

Halocarbon lubricants are built for the toughest demands.

- Shafts & Bearings: Stable film protects under heavy loads

- Seals & Valving: Protects valve seats and seal faces from wear and chemical attack

- Rotors & Vanes: Smooth motion, less vibration, higher efficiency

- High-Heat Zones: Thermal control keeps pumps cooler, longer

Halocarbon lubricants keep equipment protected, extend service life, and ensures continuous operation.

Lubricity

Equipment

Halocarbon lubricants help preserve the mechanical integrity of pumps and compressors by maintaining strong, consistent protection across moving parts. Their stable film reduces stress on shafts, bearings, and seals, preventing the small failures that lead to misalignment or premature wear. With resistance to heat and aggressive chemistries, these oils keep pump internals structurally sound, supporting longer service life and dependable operation.

Safety & Reliability

Halocarbon lubricants are engineered to safeguard operational safety in pumps and compressors exposed to harsh chemistries. Their nonflammable, chemically inert formulation removes ignition risks and prevents dangerous reactions in oxygen, chlorine, and other reactive gas environments. Stable lubrication under load and temperature extremes keeps equipment dependable, ensuring operators and processes remain protected. This balance of safe chemistry and reliable performance protects people, equipment, and production continuity.

Protecting Equipment. Preserving Performance.

Risk to Pumps, Compressors, & Vacuums | PCTFE Protection & Benefit |

Reactive gases destroy conventional lubricants and seals | Chemically inert, nonflammable oils deliver safe, stable lubrication in oxygen and fluorine service |

Corrosive environments shorten pump life and cause seal failure | Proven chlorine resistance protects seals and metal surfaces, extending equipment service intervals |

Acids rapidly break down standard oils, leading to loss of protection | Acid-resistant formulation maintains viscosity and safeguards shafts, bearings, and housings |

Reactive byproducts form sludge, fouling pumps and reducing efficiency | Fluorinated stability prevents sludge buildup, keeping pumps cleaner and more efficient |

Toxic or incompatible gases compromise lubrication films | Inert protective film shields pump internals from contamination and wear |

Lewis acids destabilize conventional oils, weakening film strength | Exceptional Lewis acid resistance preserves film integrity under demanding conditions |

High heat and catalytic reactions accelerate oil degradation | PCTFE-based stability resists breakdown, ensuring long-term performance in harsh environments |

Compatibility with the Harshest Chemicals

Halogens & Acids | Oxidizers | Lewis Acids & Catalysts | Reactive Chemicals |

Fluorine (F₂) | Oxygen (O₂, LOX/GOX) | Aluminum Chloride (AlCl₃) | Ammonia (NH₃) |

Chlorine (Cl₂) | Hydrogen Peroxide (all conc.) | Boron Trifluoride (BF₃) | Ammonium Nitrate |

Bromine (Br₂) | Nitric Acid (conc./fuming) | Boron Trichloride (BCl₃) | Ammonium Perchlorate |

Bromine Trifluoride (BrF₃, gaseous) | Nitrogen Oxides (NOₓ) | Antimony Trichloride (SbCl₃) | Hydrogen (H₂) |

Hydrofluoric Acid (HF) | Ozone (O₃) | Silicon Tetrachloride (SiCl₄) | Hydrogen Bromide (HBr) |

Hydrochloric Acid (HCl) | Sulfur Trioxide (SO₃) | Arsenic Trifluoride (AsF₃) | Hydrogen Fluoride (HF) |

Sulfuric Acid (H₂SO₄, conc./dil.) | Sulfur Dioxide (SO₂) | Titanium Tetrachloride (TiCl₄) | Hydrogen Sulfide (H₂S) |

Phosphoric Acid (H₃PO₄) | Sulfur Hexafluoride (SF₆) | Chromium (III) Nitrate | Silane |

Chromic Acid | Chlorine Dioxide (ClO₂) | Phosphorus Oxychloride (POCl₃) | Propylene Oxide |

Thionyl Chloride (SOCl₂) | Sodium Perchlorate | — | — |

Halocarbon lubricants remain stable in contact with halogens, strong acids, oxidizers, Lewis acids, and reactive gases that rapidly destroy conventional lubricants. Their nonflammable and chemically inert design prevents breakdown, sludge formation, and corrosion, ensuring longer pump life, reduced downtime, and safer operation in industries such as semiconductor manufacturing, chemical processing, and cryogenic systems.

Boost Efficiency, Safety, and Equipment Life

Oils That Fit Your Pumps & Compressors

| Product | ISO VG | Viscosity at 100°F | Application | Performance |

| InfinX MRO 27 | 32 | 27 cSt | Light-duty vacuum pumps, small compressors, fast-circulation systems | Quick startup, efficient lubrication and demand |

| InfinX MRO 56 | 68 | 56 cSt | Industrial pumps and compressors | Balanced film strength and flow; reliable across varied conditions |

| InfinX MRO 95 | 100 | 95 cSt | Heavy-duty rotary pumps, multistage compressors, high-load bearings | Thick, durable oil film; extended equipment life under high loads |

Looking for a rust inhibited option? InfinX MRO + options are available

Lubrication That Fits Your System

| Grease | Base Oil | Thickener | Operating Range | Applications |

| HaloVac 25 | PCTFE | Silica | -20°C to 175°C (0–350°F) | Valves, regulators, thread sealant, sealing joints in laboratory apparatuses |

| MRO 362 | PCTFE | Silica | -45°C to 95°C (-50°F–200°F) | Low-temperature valves, regulators, threads, O-rings |

| KF205 | PFPE | PTFE | -40°C to 204°C (-40°F–400°F) | Bearings, valves, instrumentation |

| HaloVac Ultra | PFPE | PTFE | -15°C to 288°C (5°F–550°F) | High & UHV systems, oxygen service, cleanrooms |

Oils Engineered for Low Vacuum Operation

| Product | Viscosity at 40°C (cSt) | Viscosity at 100°C (cSt) | Pour Point (°C) | Vapor Pressure at 40 °C (mmHg) |

| HaloVac 60 | 52 | 4.9 | -27 | 6.3 × 10⁻² |

| HaloVac 100 | 86 | 6.4 | -12 | 2.5 × 10⁻² |

| HaloVac 125 | 107 | 7.2 | -10 | 1.9 × 10⁻² |

| HaloVac 190 | 161 | 9.1 | -6 | 7.8 × 10⁻³ |

| Not seeing what you’re looking for – click here to view our entire low vacuum portfolio | ||||

Reliable low vacuum performance protects wafer yield, minimizes defects, and ensures semiconductor production stays efficient. Roughing pumps depend on oils that resist chemical attack at this critical stage, where aggressive halogens and Lewis acids are present. PCTFE-based Halocarbon oils versus PFPE fluids is a clear distinction – PCTFE resists Lewis acidity and maintains film integrity, while PFPE breaks down under the same conditions. For fabrication plants requiring stable, nonflammable, chemically inert oils, Halocarbon PCTFE delivers unmatched protection and consistency in low vacuum service.

Upgrade to Proven Reliability in Every Drop

Switch to Halocarbon and Create Your Breakthrough in Reliability

Not sure which grade is right?

Speak with a Halocarbon expert to match the best solution for your pumps, compressors, and process conditions.