In machining, real-world results matter more than claims. Halocarbon ran a third-party study at Kratos SRE, to quantify the benefits of Halocarbon MWF 32, a high-performance machining fluid. In these studies, Halocarbon chose a difficult-to-machine high temperature nickel alloy, nickel 718 (also known by its tradename Inconel® 718) to make a head-to-head comparison of machining fluid performance. This case study effectively serves as an Inconel® 718 cutting fluid comparison, showing how Halocarbon MWF32 performs against a leading competitor under identical conditions.

When it comes to nickel 718—a high-strength, heat-resistant nickel alloy used extensively in aerospace and defense—the right machining fluid can make or break a job. Tool wear, cycle times, and surface finish are all magnified when cutting this notoriously difficult material.

Kratos SRE conducted a rigorous machining study comparing Halocarbon MWF 32 to a competitive machining fluid. The study ran identical turning, milling, drilling and tapping operations on four nickel 718 test articles. Two were machined with Halocarbon MWF32 and two with the competitive control fluid (CCF). The results provide a clear case study of how cutting fluid selection impacts performance, cost, and reliability.

Test Setup

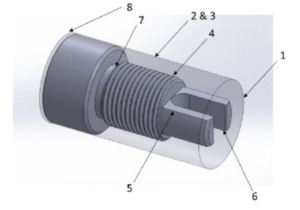

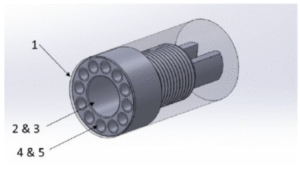

The study used the following parameters:

- 4 nickel 718 test articles (1.5” diameter x 2.94” length)

- 2 test articles machined with Halocarbon MWF32

- 2 test articles machined with a competitive control fluid (CCF)

- Minimum Quantity Lubrication (MQL) system applied fluids under identical conditions

- Operations included 13 discrete machining steps across 2 sides of the workpiece:

Side 1

- Face Milling (Milling)

- Facing (Turning)

- O.D. Finishing (Turning)

- O.D. Roughing (Turning)

- Parting Off (Turning)

- Slotting (Milling)

- Thread Relief Grooving (Turning)

- Parting Off (Turning)

Side 2

- Facing (Turning)

Rough Boring (Milling)

Rough Boring (Milling)- Finish Boring (Turning)

- Drilling (Milling)

- Tapping (Milling)

Summary of the Results:

In this Inconel® 718 cutting fluid comparison, across every major operation, Halocarbon MWF 32 matched or significantly outperformed the control fluid (a commonly used Inconel® cutting fluid):

| Operation | Articles Machined w/

Halocarbon MWF 32 |

Articles Machined w/ CCF | Halocarbon Advantage |

| Milling | Completed both articles using 1 end-mill | Required end-mill replacement (2 end-mills required) | Fewer tool changes, less downtime |

| Threading | Carbide inserts survived machining both articles | Carbide insert fractured mid-cut

(gouged article) |

More reliable threading, fewer tool changes, less downtime, no off spec. parts |

| Tapping | 17 out of 24 holes tapped before tool replacement | Failed

0 out of 24 holes tapped |

Critical differentiator |

| Drilling | Completed operations with minimal wear | Completed operations with significant wear. Required insert replacement | Longer insert life |

| Surface Finish | Bore roughness 11-12 µin RA | Bore roughness 25-26 µin RA | 54% smoother finish |

| Cycle Time | 59 minutes per part | 70 minutes per part | 15% faster throughput |

Milling Performance

The milling operations (slotting, face milling, boring) highlighted tool life differences:

- Halocarbon MWF32: One 3/8” carbide end-mill was able to complete machining of both test articles

- Competitive Control Fluid (CCF): Two 3/8” carbide end-mills were required to finish the same work, adding downtime and creating off-spec components

Halocarbon MWF: 3/8” Carbide end-mill after machining test articles using Halocarbon MWF 32.

Competitive Fluid: Two separate 3/8” Carbide end-mills after machining test articles using Competitive Control Fluid (CCF).

Threading Performance

In outside diameter (O.D.) threading:

- Halocarbon MWF32: Allowed for the machining of both test articles, and the threading insert would have continued life to machine additional workpieces.

- Competitive Control Fluid (CCF): The insert used in the CCF machining operation fractured during the machining of the second test article. Inspection of the insert post-machining showed significant damage to the insert, requiring replacement prior to continuing operations on additional workpieces.

Halocarbon MWF: Carbide threading insert remained intact after machining both test articles using Halocarbon MWF 32.

Competitive Fluid: Carbide threading insert failure when using Competitive Control Fluid (CCF).

In addition to catastrophic tool failure during threading operations on nickel 718, the competitive control fluid also gouged the workpiece, rendering it off-spec for the application.

Competitive Fluid: Carbide threading insert failure left significant gouging in the workpiece when using Competitive Control Fluid (CCF).

Tapping Performance

The most significant difference was observed in tapping with a ¼”-20 UNC tap. These data show the critical nature of choosing the right metalworking fluid during the machining of difficult-to-machine alloys. In this case, the Halocarbon MWF 32 delivered breakthrough results in the highly-demanding application of tapping nickel 718.

- Halocarbon MWF32: Completed 17 threaded holes before breaking on the 18th.

- Competitive Control Fluid (CCF): Could not complete even one hole.

Halocarbon MWF: 17 holes out of 24 successfully tapped using Halocarbon MWF 32

Competitive Fluid: Could not tap even one hole when using Competitive Control Fluid (CCF), resulting in 0 out of 24 holes tapped.

Surface Finish

Surface quality was measured as a function of surface roughness. In this study, surface roughness was measured in two separate tests: (1) bore roughness and (2) milled flat roughness. In both cases, surface quality was consistently better with Halocarbon MWF 32.

- Bore roughness: 11–12 µin Ra with Halocarbon MWF 32 vs. 25–26 µin Ra with CCF (~54% improvement).

- Milled flats: 10.3 µin Ra with Halocarbon MWF 32 vs. 13.5 µin Ra with CCF (~24% improvement).

In addition, only one end-mill was required to complete this process when using Halocarbon MWF 32. In the case of the CCF, catastrophic tool failure required two end-mills to complete this process. This equates to extended tool life without compromising surface finish.

| Surface Roughness, Ra (micro-inches, µin) | ||||

| Machining Fluid | Hole Position 1 | Hole Position 2 | Hole Position 3 | Hole Position 4 |

| Halocarbon MWF 32 | 11 | 11 | 12 | 12 |

| Competitive Control Fluid | 26 | 26 | 25 | 26 |

| Average Surface Roughness, Ra (micro-inches, µin) | ||||

| Machining Fluid | Flat 1 0° | Flat 1 90° | Flat 2 0° | Flat 2 90° |

| Halocarbon MWF 32 | 13.0 | 7.5 | 13.0 | 7.5 |

| Competitive Control Fluid | 15.5 | 11.5 | 15.0 | 12.0 |

Surface Finish of Flat Surface: Measured in 2 dimensions. 0° is represented by the red arrow, going along the horizontal surface of the flat surface. 90° is represented by the red X, going into the plane of the picture.

Cycle Time Improvements

In Inconel® 718 and other difficult-to-machine alloys, Halocarbon metalworking fluids (MWF) have demonstrated significant improvements to cycle time. These improvements are directly correlated to improved tool life, reduced downtime, improved surface finish, and higher workpiece quality (requiring less re-work or changes operating parameters or feed rates). In the head-to-head comparison on nickel 718, the total machining time of each test article was 15% lower when using Halocarbon MWF 32, including the successful tapping of 18 holes versus the competitive control fluid (CCF), which was not able to successfully tap even one hole.

- Halocarbon MWF32: ~59 minutes per part

- Competitive Control Fluid (CCF): ~70 minutes per part

Halocarbon MWF: Finished machined test articles that utilized Halocarbon MWF 32.

Competitive Fluid: Finished machined test articles that utilized Competitive Control Fluid (CCF).

Conclusion: Proof of Performance

This case study demonstrates that cutting fluid is far more than a background variable. In machining Inconel® 718, Halocarbon MWF32 consistently extended tool life, improved surface finish, reduced downtime, and shortened cycle time compared to a leading competitor fluid.

For aerospace and defense engineers, these gains translate directly into lower costs, higher throughput, and fewer rejected parts. The study confirms what many overlook: the right machining fluid can be a decisive factor in high-performance manufacturing.

Halocarbon MWF is now InfinX MWF, buy here.