Machining & Metalworking

Machining & Metalworking Fluids for High-Performance Alloys

Halocarbon Metalworking Fluids are purpose-built for one challenge: machining the metals that others can’t. High-temperature alloys and refractory metals provide strength, oxidation resistance, and corrosion resistance in service — but these same properties make them extremely difficult to machine.

Halocarbon MWFs solve this problem by delivering superior cooling. reliable lubrication and unique chip formation, enabling:

- Cleaner chip formation

- Faster machining throughput

- Extended tool life under extreme heat and pressure

- Exceptional surface finish on critical components

Where traditional coolants fail, Halocarbon MWFs deliver consistent, repeatable performance, even in the most demanding operations.

The Ultimate Edge in Machining Performance

Halocarbon MWFs are trusted in industries where component integrity cannot be compromised. By overcoming the limitations of conventional coolants, they enable cleaner cuts, smoother surfaces, and longer tool life across the most demanding industries:

- Aerospace – Propulsion systems & high-heat structural components

- Energy – Fusion reactor, gas turbines, furnace components, sputtering targets

- Defense – Missile & ordnance components, gun barrels

- Biomedical – Surgical tools, metallic implant materials, X-ray targets

- Industrial – Chemical process equipment, crucibles, high-wear tooling, additive manufacturing

- Performance Automotive – Turbochargers, racing components, dies, precision tooling

Engineers and machinists across these fields choose Halocarbon MWFs to achieve reliable surface quality, extended tool performance, and reduced machining variability — even in materials traditionally considered unmachinable.

Not seeing what you are looking for? Please contact our team of technical experts to find the right solution for your needs.

Aerospace & Defense

Halocarbon Metal Working Fluids are specifically formulated to enable the machining of difficult-to-machine metals and alloys that are used in high-temperature and high-strength materials within the aerospace industry. These are materials comprised of tungsten, molybdenum, or titanium, or high temperature alloys like Inconel, and are used to manufacture heat-shielding or high-stress structural components. In these applications, Halocarbon MWFs provide exceptional tool life, higher machining efficiency and throughput, and superior surface finish and quality when compared to conventional machining fluids and coolants.

Not seeing what you are looking for? Please contact our team of technical experts to find the right solution for your needs.

Microelectronics

Halocarbon MWFs provide exceptional surface finish and quality in many microelectronics applications. These fluids are used for machining metals and alloys of tantalum and niobium and are used in applications such as wire-drawing for capacitors or low surface-roughness grinding and polishing of electronics-grade sputtering targets. Halocarbon metalworking fluids can be used with conventional machining tools to achieve exceptional performance and throughput while minimizing tool wear and product defects.

Not seeing what you are looking for? Please contact our team of technical experts to find the right solution for your needs.

Medical Devices

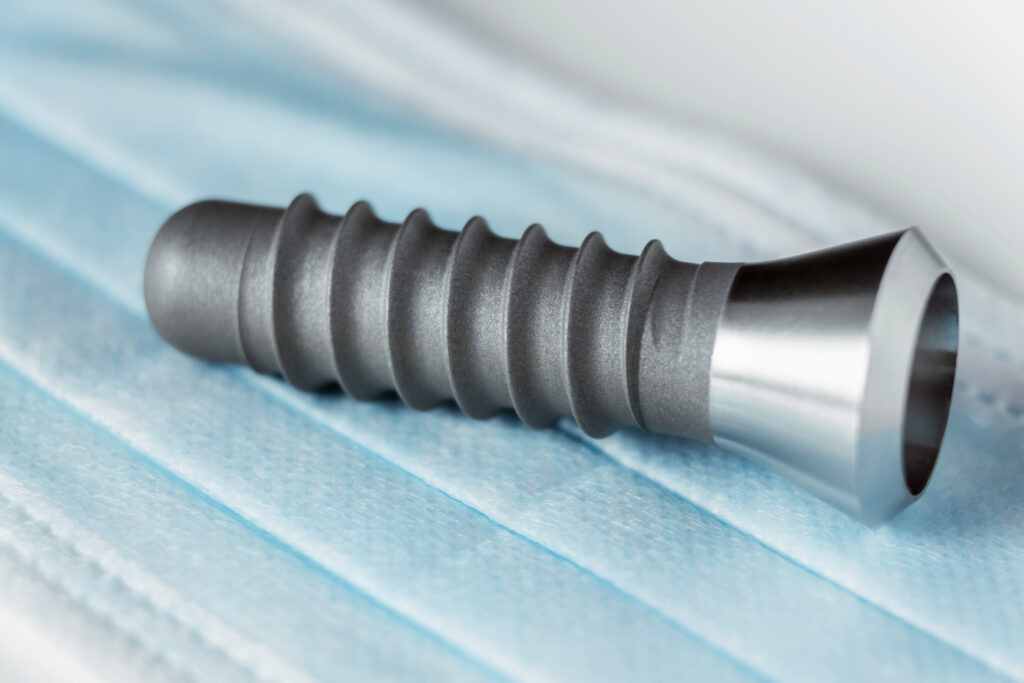

Halocarbon MWFs provide superior surface finish in the machining of tantalum and titanium parts, making them ideal for use in the fabrication of implant-grade medical devices and components, where tight tolerances and precision control over surface features are of importance. These fluids are chemically inert and do not require the use of a biocide, and can be easily cleaned from the finished component using conventional cleaning solvents and processes.