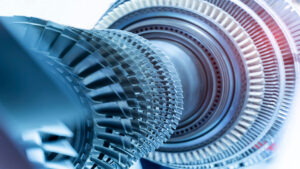

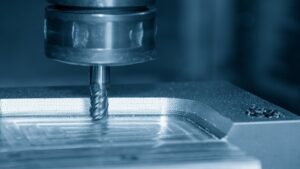

Surface Finish Matters: Achieving Aerospace-Grade Quality in Nickel 718

In aerospace and defense machining, surface finish isn’t about aesthetics—it’s about performance, reliability, and certification. For superalloys like Nickel 718 (also known by its tradename Inconel® 718), achieving the right surface finish can mean the difference between a component that passes inspection and one that gets scrapped.