When machining titanium alloys like Ti-6Al-4V (sometimes called TC4, Ti64, or ASTM Grade 5), machinists face a set of stubborn challenges: high friction, galling, and excess heat. These issues not only shorten tool life but also drive up costs for critical components needed in aerospace, marine, automotive lightweighting, and medical device applications.

Halocarbon Metalworking Fluids (MWFs) have helped machinists overcome these challenges and can also provide advantages other titanium machining fluids can’t. At their core, Halocarbon MWFs are engineered to provide excellent lubricity during machining – significantly reducing the coefficient of friction in titanium machining.

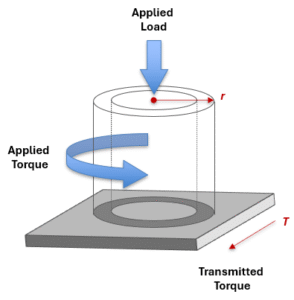

Engineers have long struggled to evaluate titanium machining fluids in a way that reflects real cutting conditions, which is where the twist compression test provides unique insight. The twist compression test is a proven way to evaluate how cutting fluids can address friction and wear, offering a controlled method to measure friction under machining-like conditions.

What is a Twist Compression Test?

The twist compression test is designed to replicate the frictional forces that occur at the tool–workpiece interface. In the test, two metal surfaces are pressed together under a set load while one surface is rotated. By measuring the torque required to rotate the surfaces, engineers can calculate the coefficient of friction (COF), a key metric for predicting how a fluid will perform during real machining operations.

- Two metal surfaces are pressed together under load.

- One surface is rotated (“twisted”) while torque is measured.

- The test quantifies the coefficient of friction (COF) under machining-like contact.

Why It Matters in Titanium Machining

Titanium alloys suffer from poor thermal conductivity. This makes titanium alloys notoriously difficult to machine because they generate high levels of friction and heat. This not only accelerates tool wear but also increases the risk of galling and chip welding—two common causes of tool failure. Reducing the coefficient of friction through an effective cutting fluid is critical to improving performance and lowering costs.

Key takeaways:

- Titanium is prone to high COF, galling, and chip welding.

- Lower COF means reduced cutting forces, less heat, and longer tool life.

The Halocarbon Advantage

In twist compression testing, Halocarbon Metalworking Fluids (MWFs) demonstrated a dramatic improvement over conventional titanium machining fluids. By lowering the coefficient of friction by approximately 50%, Halocarbon MWFs created a more stable tool–workpiece interaction. This translates directly to smoother cuts, less galling, and improved tool reliability when machining titanium alloys.

Relative to conventional titanium machining fluids and alternative coolants for machining titanium alloys, the Halocarbon MWF (orange line) had the longest time before breakdown, and an average coefficient of friction (COF) of only 0.25.

Key takeaways:

- Halocarbon MWFs reduced COF by ~50% versus competitive titanium machining fluid

- This performance translates into smoother cuts, less galling, and better tool reliability in real-world machining.

Conclusion

Twist compression testing offers a clear and measurable way to demonstrate the advantages of Halocarbon fluids in titanium machining. By significantly reducing the coefficient of friction, Halocarbon MWFs help extend tool life, reduce downtime, and improve part quality. For aerospace manufacturers, that’s a proven path to lower costs and higher confidence in machining mission-critical metals.

Don’t Forget the Halocarbon Advantage

Halocarbon MWFs aren’t just another machining fluid—they’re a proven performance enhancer across the toughest alloys.

Halocarbon MWF is now InfinX MWF, buy here.